KODDA 150 MW

KODDA 150 MW DUAL FUEL POWER PLANT PROJECT

An engineering solution to a logistic problem

Name of the Project: Kodda 150 MW Dual-Fuel Power Plant at Gazipur, Bangladesh. Contractor: CCC Engineering Ltd., China.

Assignment: CCC Engineering Ltd. Engaged Avant-Lisa JV to transport 9 units of MAN Engines and 9 units of Alternators from Mongla Sea Port, Bangladesh to Kodda Project Site, along with full specification of the project.

The engines were MAN 18V 51/60, each weighing 325 tons each and Alternators were 71 ton each.

In compliance with the requirement of the Insurance Company, RSA of Singa- pore, the following documents were provided to meet the safety aspects:

01. Barge deck load capacity with all engineering calculation.

02. Barge stability calculation with loaded engines with CG, KG etc.

03. Bollards pull capacity calculation of Tugs.

04. Towing speed calculation of Barges when tugs pulling.

05. Stowage and lashing detail calculation with drawings

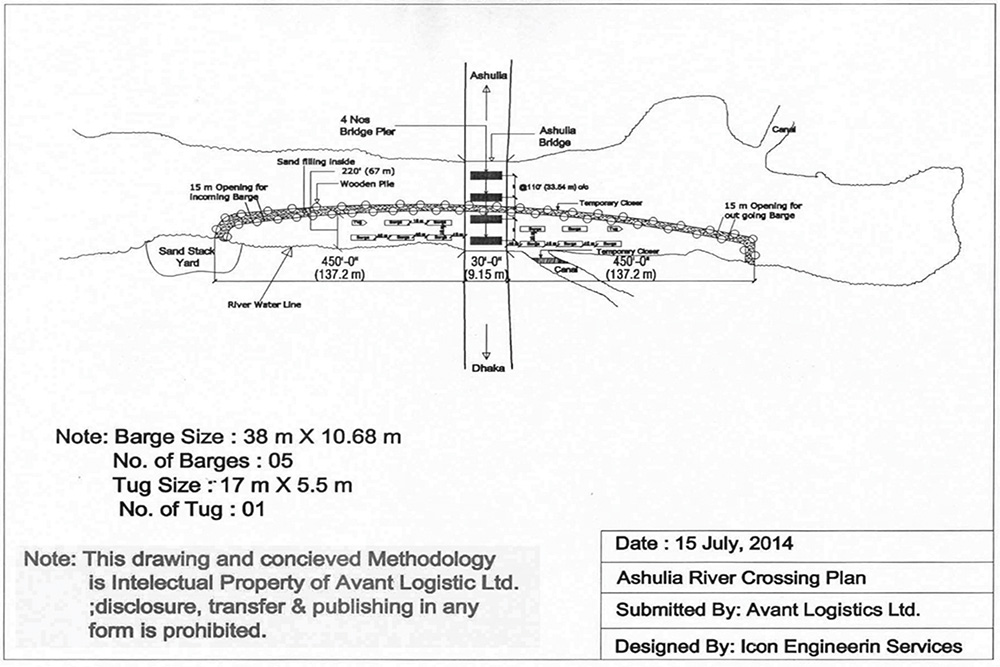

In assessing the job, it was found that there was no possibility in transportation by road particularly for engines because of the weight (325) ton and head clearance. The road and bridges could not support this load. The only possibility was to transport by river. On the river route, at Ashulia, Dhaka, there is a Bridge on River Turag and during the period of transportation, there was only a clearance of 5.5 m between river water level and bottom of the bridge girder, whereas a clearance of 7.5 m was required including the free board of barges.

Mr. Mashiur Rahman, MD of AVANT conceived an idea to solve this problem. He suggested of lowering the river water level towards safe passage of the Engine Barges by making an enclosure as a bypass.

The design was to construct an enclosure 3 m wide with wooden piles and fill inside of enclosure with dredged sand.

Such enclosure acted like a sand gravity wall on the river, isolating the main river flow. At the construction stage, water level inside the enclosure and main river flow was same. A total of 2,800 wooden piles, each 9 m long used for the enclo- sure of which 4 m was driven into the river bed. Bamboo sheet, geo-textile, sand bags, sheet piles were used to make the enclosure wall water tight. 14,158 m3 sand was put inside the enclosure wall.

There was on open passage to allow the 5 Engine Barges to enter inside the enclo- sure. After the Engine barges entered, the opening was closed isolating the enclo- sure with the main river flow. Seepage of water through the Sand gravity wall of the enclosure was allowed to avoid differential hydrostatic pressure in course of lowering water level inside.

4,250 sq.m space was kept at both the sides of the bridge to accommodate all the 5 barges and 1 tug at either side of the bridge.

Three floating pumps having a total capacity of 2,660 m3/hr were used to pump out water from the enclosure.

After all the Barges entered the enclosure and the entering passage closed, pump- ing operation was started with all the pumps working simultaneously. At the time of operation, bridge girder to water level clearance was 6.0 m and a water level lowering of 1.5 m was required to allow safe passage of the barges. By calculated pumping with intensive monitoring of time versus water level recession, in the 1st hour, 0.45 m water level was lowered. Pumping operation continued and after 3 hours of pumping desired lowering of 1.5 m water level was achieved. All the barges were ballasted almost to the full capacity for extra clearance.

With safe head clearance, one after one barges crossed below the bridge girders to other side of the ridge. Total operational time to cross all barges, was 16 hrs.

Another gate of the enclosure on the opposite side was opened to allow the water to flow in, making the inside water, level with outside water. Barges were then released from the enclosure for onward voyage to Kodda Power Plant.

The whole operation took only 16 (sixteen) hours.

Marine Care, an internationally reputed surveyor, monitored each step of the job.

Cofferdam in Turag river under Ashulia bridge under construction – Kodda Project

325 Ton MAN Engines are unloaded onto the Barge – Kodda Project

325 Ton MAN Engine waiting to cross Ashulia bridge

325 Ton MAN Engine waiting to cross Ashulia bridge